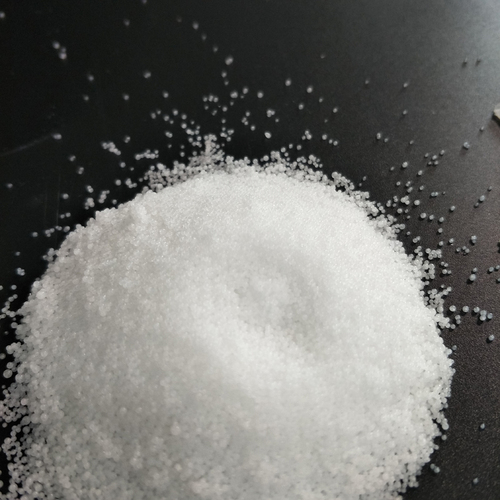

Bentonite Powder

Bentonite Powder Specification

- Shape

- Fine powder

- Melting Point

- Not applicable / decomposes

- Structural Formula

- (Na,Ca)0.33(Al,Mg)2Si4O10(OH)2nH2O

- Taste

- Earthy, bland

- Form

- Powder

- Smell

- Odorless

- Molecular Formula

- Al2H2Na2O13Si4 (typical for sodium bentonite)

- Refractive Rate

- 1.48 approx.

- Storage

- Store in a cool, dry place, keep away from moisture

- Poisonous

- Yes

- Solubility

- Insoluble in water, swells when mixed with water

- Purity

- 95% min (varies by supplier)

- Ph Level

- 8-10 (1% solution)

- Other Names

- Bentonite Clay, Sodium Bentonite, Calcium Bentonite, Potassium Bentonite

- Molecular Weight

- Varies, approx. 422.28 g/mol (for pure compound)

- HS Code

- 250810

- Density

- 1.2 Gram per cubic centimeter(g/cm3)

- Classification

- Hydrated aluminosilicate clay

- Chemical Name

- Bentonite

- CAS No

- 1302-78-9

- EINECS No

- 215-108-5

- Grade

- Technical grade, Industrial grade

- Standard

- IS:6186

- Type

- Natural sodium bentonite, Natural calcium bentonite, Potassium bentonite, Calcium bentonite, Sodium bentonite

- Usage

- Industrial, Agricultural, Cosmetic, Pharmaceutical

- Main Material

- Bentonite clay (Naturally occurring clay)

- Application

- Drilling mud, foundry, binding agent, oil & gas, cosmetics, pharmaceuticals, civil engineering

- Swelling Index

- 2432 ml/2g (for sodium bentonite)

- Cation Exchange Capacity

- 6080 meq/100g

- Color

- Off-white to cream or light grey

- Particle Size

- 200325 mesh (customizable)

- Moisture Content

- <12%

- Oil Absorption

- 5060%

Bentonite Powder Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T), Western Union, Cash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1000 Kilograms Per Day

- Sample Available

- Yes

- Main Domestic Market

- All India

About Bentonite Powder

Sodium bentonite

Calcium bentonite

bentonite powder,Natural sodium bentonite Natural calciumbentonite calcium bentonite Sodium bentonite Calcium bentonite Potassiumbentonite Bentonite Clay Sodium Bentonite Bentonite Powder Bentonite PowderCalcium Bentonite Bentonite Drilling Mud

High Versatility and Performance

Bentonite Powders natural swelling, oil absorption, and binding properties make it indispensable in industries such as drilling, foundry, and civil engineering. Sodium and calcium bentonite grades offer tailored benefits for specific applications, while its fine particle size ensures uniformity in various formulations. Its environmental friendliness and inertness further enhance its appeal.

Quality and Customization

Available as technical and industrial grades, this bentonite powder meets IS:6186 standards and offers over 95% purity (varies by supplier). Customizable mesh sizes cater to diverse requirements, while the products stable pH (810) and consistent density ensure reliable performance across industrial, cosmetic, and agricultural scenarios.

FAQs of Bentonite Powder:

Q: How is bentonite powder typically used in industrial and agricultural applications?

A: Bentonite powder is commonly used as a drilling mud in oil and gas exploration, a binding agent in foundries, and a soil conditioner in agriculture. Its swelling properties and cation exchange capacity enhance stability and nutrient retention in these settings.Q: What makes sodium bentonite different from calcium bentonite?

A: Sodium bentonite swells significantly when mixed with water and is ideal for sealing and drilling mud, while calcium bentonite has less swelling capacity but provides better binding, making it suitable for foundry and construction applications.Q: When should I use bentonite powder in cosmetic or pharmaceutical formulations?

A: You should use bentonite powder when you need natural thickening, absorption, or cleansing properties in masks, creams, or ointments. Its high purity and inert nature make it suitable for skin and pharmaceutical uses, subject to regulatory approval.Q: Where is the best place to store bentonite powder to maintain its quality?

A: Store bentonite powder in a cool, dry area away from moisture to prevent clumping and preserve its swelling and absorption properties. Proper storage ensures the products longevity and effectiveness.Q: What benefits does bentonite powder provide as a binding and absorbent material?

A: Bentonite powders fine particle size enables excellent binding and absorption of oils and impurities. These attributes are especially beneficial in foundry applications, wastewater treatment, and cosmetics where efficient absorption and stability are key.Q: How is bentonite powder processed before it is ready for industrial use?

A: After mining, bentonite clay is crushed, dried to reduce moisture, and milled to the desired mesh size. Quality control ensures it meets the required specifications for industrial, cosmetic, or agricultural applications.Q: What standards and specifications apply to bentonite powder supplied in India?

A: Bentonite powder usually adheres to IS:6186 standards for technical and industrial grades, and must meet purity, particle size, and performance criteria set by Indian regulations and industry requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Speciality Chemicals Category

Gum Rosin

Price 75.0 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Usage : Gum Rosin is used in the manufacture of paper, inks, paints, adhesives, rubber, soaps, chewing gum and many industrial applications. Yellow Solid Gum Rosin Ww Grade , Yellow Crystal Gum Rosin Ww Grade, Yellow Gum Rosin WW Grade Yellow Solid Gum Rosin Ww Grade WW Grade Rosin Gum Rosin Grade Gum Rosin Grade Gum Rosin Grade WG N Grade Rosin M Grade Rosin K Grade Rosin H Grade Rosin D Grade Rosin X Grade Rosin Modified Rosin Hydrogenated Rosin Disproportionated Rosin Maleic Modified Rosin Polymerized Rosin

Melting Point : Gum Rosin is used in the manufacture of paper, inks, paints, adhesives, rubber, soaps, chewing gum and many industrial applications. Yellow Solid Gum Rosin Ww Grade , Yellow Crystal Gum Rosin Ww Grade, Yellow Gum Rosin WW Grade Yellow Solid Gum Rosin Ww Grade WW Grade Rosin Gum Rosin Grade Gum Rosin Grade Gum Rosin Grade WG N Grade Rosin M Grade Rosin K Grade Rosin H Grade Rosin D Grade Rosin X Grade Rosin Modified Rosin Hydrogenated Rosin Disproportionated Rosin Maleic Modified Rosin Polymerized Rosin

Main Material : Gum Rosin is used in the manufacture of paper, inks, paints, adhesives, rubber, soaps, chewing gum and many industrial applications. Yellow Solid Gum Rosin Ww Grade , Yellow Crystal Gum Rosin Ww Grade, Yellow Gum Rosin WW Grade Yellow Solid Gum Rosin Ww Grade WW Grade Rosin Gum Rosin Grade Gum Rosin Grade Gum Rosin Grade WG N Grade Rosin M Grade Rosin K Grade Rosin H Grade Rosin D Grade Rosin X Grade Rosin Modified Rosin Hydrogenated Rosin Disproportionated Rosin Maleic Modified Rosin Polymerized Rosin

Solubility : Gum Rosin is used in the manufacture of paper, inks, paints, adhesives, rubber, soaps, chewing gum and many industrial applications. Yellow Solid Gum Rosin Ww Grade , Yellow Crystal Gum Rosin Ww Grade, Yellow Gum Rosin WW Grade Yellow Solid Gum Rosin Ww Grade WW Grade Rosin Gum Rosin Grade Gum Rosin Grade Gum Rosin Grade WG N Grade Rosin M Grade Rosin K Grade Rosin H Grade Rosin D Grade Rosin X Grade Rosin Modified Rosin Hydrogenated Rosin Disproportionated Rosin Maleic Modified Rosin Polymerized Rosin

Questoll 591

Price 84.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Usage : Industrial

Melting Point : 9094C

Main Material : Alcohol ethoxylate blend

Solubility : Soluble in water and organic solvents

colour pigment

Price 100 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Usage : Pigment Powder Dyes , Liquid Solvent Dyes , Metal Complex Solvent Dyes , Vat Dyes , Acid Dyes, Pigments For Cosmetics Acid Colour , Water colour , Toilet cleaner colour powder , phenyl colour powder

Melting Point : Pigment Powder Dyes , Liquid Solvent Dyes , Metal Complex Solvent Dyes , Vat Dyes , Acid Dyes, Pigments For Cosmetics Acid Colour , Water colour , Toilet cleaner colour powder , phenyl colour powder

Main Material : Pigment Powder Dyes , Liquid Solvent Dyes , Metal Complex Solvent Dyes , Vat Dyes , Acid Dyes, Pigments For Cosmetics Acid Colour , Water colour , Toilet cleaner colour powder , phenyl colour powder

Caustic Soda

Minimum Order Quantity : 1 Kilograms

Usage : Caustic Soda Prills / caustic soda / sodium hydroxide flakes

Melting Point : Caustic Soda Prills / caustic soda / sodium hydroxide flakes

Main Material : Caustic Soda Prills / caustic soda / sodium hydroxide flakes

Solubility : Caustic Soda Prills / caustic soda / sodium hydroxide flakes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS