Polyacrylamide Chemical

Polyacrylamide Chemical Specification

- Storage

- Store in cool, dry place, keep container tightly closed

- Packaging Type

- 25 kg Bag

- Shelf Life

- 2 years

- Solubility

- Easily Soluble in Water

- CAS No

- 9003-05-8

- Chemical Name

- Polyacrylamide

- Physical Form

- Powder

- Grade

- Industrial Grade

- Purity(%)

- 98%

- Type

- Chemical Flocculant

- Application

- Industrial Water Treatment, Paper Making, Oil Field, Textile, Mining, Sludge Dewatering

Polyacrylamide Chemical Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 1 Week

About Polyacrylamide Chemical

Broad Applications Across Industries

Polyacrylamide is extensively used across diverse sectors, including industrial water treatment, paper manufacturing, oil fields, textile, mining, and sludge dewatering processes. Its capacity to act as a highly efficient chemical flocculant makes it invaluable for separating solids from liquids and improving overall process efficiency.

High Purity and Industrial Performance

With a purity level of 98% and an industrial-grade formulation, polyacrylamide ensures optimal results in demanding environments. Its high molecular weight and variety in ionic types (anionic, cationic, and nonionic) allow for tailored performance according to specific application requirements, ensuring reliable and consistent outcomes.

Safe Handling and Storage

Polyacrylamide is non-toxic, odorless, and safe for industrial use when basic safety practices are followed. Store it in a cool, dry place in tightly closed containers to maintain its effectiveness. Thanks to its stable powder form and high melting point, it boasts a long shelf life of two years, minimizing waste and ensuring supply readiness.

FAQs of Polyacrylamide Chemical:

Q: How is polyacrylamide typically used in industrial water treatment?

A: Polyacrylamide acts as a chemical flocculant that binds suspended particles, making them easier to remove during water treatment processes. Its high molecular weight and solubility facilitate rapid coagulation and clearer effluent without toxic residues.Q: What are the advantages of using polyacrylamide for sludge dewatering?

A: Polyacrylamides high viscosity and strong flocculating capabilities significantly improve sludge dewatering efficiency, reducing sludge volume and lowering disposal costs. Its non-toxicity ensures safe handling and minimal impact on downstream processes.Q: When should I use anionic, cationic, or nonionic polyacrylamide?

A: The choice depends on the application and the nature of the substances to be treated. Anionic types are suitable for mineral processing and wastewater with inorganic particles, cationic for organic-rich effluents and sludge, and nonionic for neutral or low-ionic strength solutions.Q: Where should polyacrylamide be stored to preserve its quality?

A: To maintain its effectiveness, polyacrylamide should be stored in a cool, dry place, away from direct sunlight and moisture. Always keep the container tightly closed to avoid contamination and degradation.Q: What is the process for preparing a polyacrylamide solution for industrial use?

A: Gradually add polyacrylamide powder to water under mild agitation to ensure complete dissolution. For a 1% solution, maintain the pH between 49 and use immediately after preparation for best performance.Q: What are the key benefits of using polyacrylamide in paper making and mining industries?

A: In paper making, polyacrylamide improves pulp retention and drainage, enhancing product quality. In mining, it aids in solid-liquid separation and tailings management, resulting in clearer effluent and reduced environmental impact.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Water Treatment Chemicals Category

Hydrated Lime Chemical

Minimum Order Quantity : 25 Kilograms, ,

Chemical Name : Other, Calcium Hydroxide

CAS No : 1305620

Type : Other, Powder

Physical Form : Powder

Grade : Industrial Grade

Poly Aluminium Chloride Chemical

Minimum Order Quantity : 25 Kilograms

Chemical Name : Other, Poly Aluminium Chloride

CAS No : 1327419

Type : Other, Chemical Coagulant

Physical Form : Powder

Grade : Industrial Grade

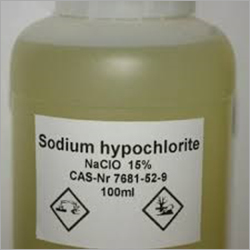

100ml Sodium Hypochlorite

Minimum Order Quantity : 25 Kilograms

Chemical Name : Other, Sodium Hypochlorite

CAS No : 7681529

Type : Other, Liquid Chemical

Physical Form : Liquid

Grade : Other, Industrial & Laboratory Grade

Caustic Soda Powder

Minimum Order Quantity : 25 Kilograms, ,

Chemical Name : Other, Sodium Hydroxide

CAS No : 1310732

Type : Other, Caustic Soda Powder

Physical Form : Powder

Grade : Industrial Grade

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS