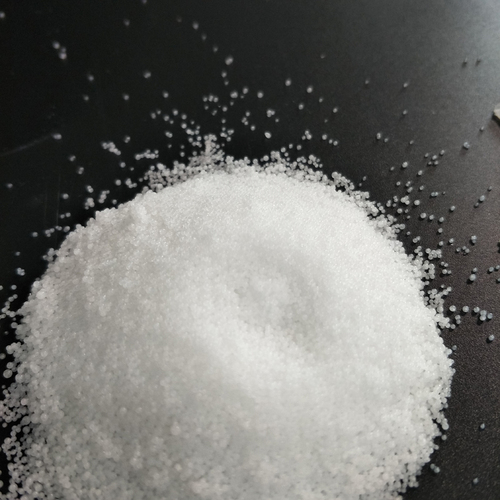

Aluminium Powder

Price 95 INR/ Kilograms

MOQ : 1 Kilograms

Aluminium Powder Specification

- HS Code

- 7603

- Melting Point

- 660C

- Storage

- Store in a cool, dry place, keep container tightly closed

- Smell

- Odorless

- Molecular Formula

- Al

- Form

- Powder

- Structural Formula

- Al

- Poisonous

- Yes

- Molecular Weight

- 26.98 g/mol

- Solubility

- Insoluble in water, soluble in acids and alkalis

- Purity

- 99% min

- Ph Level

- N/A (Not Applicable)

- Shape

- Fine powder

- Boiling point

- 2467C

- Other Names

- Aluminum metal powder, Atomized Aluminium Powder

- Taste

- Tasteless

- Density

- 2.7 Gram per cubic centimeter(g/cm3)

- Classification

- Metallic powder

- Chemical Name

- Aluminium

- CAS No

- 7429-90-5

- EINECS No

- 231-072-3

- Grade

- Industrial Grade

- Standard

- As per IS 438-1977

- Type

- Powder

- Usage

- Industrial, chemical reaction agent, reducing agent

- Main Material

- Aluminium

- Application

- Pyrotechnics, paints, metallurgy, explosives, pigments, additive in construction materials

- Packaging

- Available in 25 kg bags or as specified

- Color

- Silver-grey

- Surface Area

- High, depends on grade

- Hazards

- Dust may form explosive mixtures with air; avoid sources of ignition

- Apparent Density

- 0.15 - 0.25 g/cm

- Shelf Life

- 2 years under recommended storage conditions

- Flash Point

- Not applicable, but dust may be flammable

- Particle Size

- 10-100 micron

- Moisture Content

- 0.25%

- Oxidizability

- High, reacts with air and moisture

Aluminium Powder Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Packaging Details

- Aluminium powder , Aluminium Metal Powder

- Main Domestic Market

- All India

- Certifications

- Aluminium powder , Aluminium Metal Powder

About Aluminium Powder

Features:- Highly pure

- Durability

- Corrosion resistance

Other details:

- ALUMINIUM (FINE POWDER)

- Al At.W. 26.98

- Assay min. 99.7%

- Maximum Limits of Impurities :

- Iron 0.17%

- Copper 0.00159%

- Silicon 0.1313%

- Manganese 0.0023%

- Magnesium 0.00160%

- Zinc 0.0053%

- CAS No : 7429-90-5

- Un No. NR

- HS Code : 7603 10 10

- F : 27

Industrial Versatility

Aluminium Powders wide range of particle sizes and high purity ensure its suitability across various sectors. Its favored for applications in pyrotechnics, paints, metallurgy, and explosives due to its high reactivity and consistent quality. The powders surface area enhances its effectiveness as a reducing agent and additive, delivering value in both chemical reactions and construction materials.

Safe Handling and Storage

Given its high oxidizability and flammability in dust form, proper handling and storage of Aluminium Powder are essential. Keep the container tightly sealed, and store it in a cool, dry place to avoid moisture and minimize risk. Avoid sources of ignition, and use protective equipment to prevent inhalation of fine dust, as it may cause respiratory irritation.

Packaging and Quality Assurance

Available in 25 kg bags or as specified by customers, Aluminium Powder is manufactured to IS 438-1977 standards, ensuring consistent quality, purity (99% min), and safety. Each batch undergoes rigorous checks for apparent density, moisture content, and surface area to meet the demands of diverse industrial applications.

FAQs of Aluminium Powder:

Q: How should Aluminium Powder be safely handled and stored?

A: Aluminium Powder should be kept in a cool, dry place, with the container tightly closed. Avoid exposure to moisture and sources of ignition, as airborne dust may form explosive mixtures. Use protective gear to prevent inhalation or contact with skin, and ensure storage areas are well-ventilated.Q: What are the main industrial applications of Aluminium Powder?

A: This powder is widely used in pyrotechnics, paints, metallurgy, explosives, pigments, and as an additive in construction materials. Its high reactivity and fine particle size make it valuable as a chemical reaction and reducing agent in various manufacturing processes.Q: When does Aluminium Powder require replacement or disposal?

A: Aluminium Powder retains its properties for up to two years under recommended storage conditions. After this period, or if exposed to moisture or contamination, the powder should be replaced to ensure safety and efficacy in application.Q: Where can Aluminium Powder be sourced in India?

A: Aluminium Powder is supplied by manufacturers, wholesalers, and traders across India, with packaging typically in 25 kg bags or customized according to client needs. Ensure procurement from a reputable supplier following IS 438-1977 standards for quality assurance.Q: What benefits does Aluminium Powder offer over other metallic powders?

A: Its high purity (99% min), fine particle size, and significant surface area contribute to superior reactivity and efficiency in chemical and industrial processes. These features facilitate rapid reactions and enhance outcomes in applications such as metallurgy, paints, and catalyst formulations.Q: How is Aluminium Powder typically used in manufacturing?

A: The powder is integrated as a reactive agent in chemical synthesis, used for producing pyrotechnic effects, forming metallic paints, and serving as a reducing agent in metallurgy. It is also added to concrete and explosive formulations to alter physical and chemical properties.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Speciality Chemicals Category

Questoll 591

Price 84.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : Other, Anticaking agent for fertilizers (Urea, NPK, DAP)

Usage : Industrial

Melting Point : 9094C

Storage : Other, Store tightly closed in a cool, dry place

silicon oil

Price 65 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Application : Industrial

Storage : Room Temperature

Caustic Soda

Minimum Order Quantity : 1 Kilograms

Usage : Caustic Soda Prills / caustic soda / sodium hydroxide flakes

Melting Point : Caustic Soda Prills / caustic soda / sodium hydroxide flakes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS