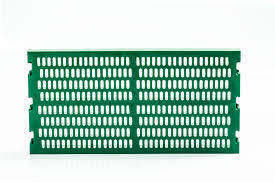

Polyurethane Screen Panel

Price 3500 INR/ Piece

Polyurethane Screen Panel Specification

- Classification

- Industrial Screens

- Type

- Polyurethane Screen Panel

- CAS No

- 9009-54-5

- EINECS No

- 618-498-9

- Grade

- Industrial Grade

- Purity

- 99%

- Application

- Vibrating Screen, Mining, Aggregates, Sieving

- Color

- Yellow

- Form

- Panel

- Size

- Standard and Customized Sizes Available

- Material

- High-Quality Polyurethane

- Opening Type

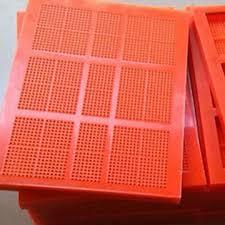

- Square, Slotted, Fine Mesh

- Usage

- Wet and Dry Screening

- Thickness

- 15mm to 50mm

- Tension Strength

- High Tensile Strength

- Hardness

- 60-95 Shore A

- Customization

- Available upon request

- Lifespan

- Long Service Life

- Surface Finish

- Smooth/Anti-Clogging

- Installation

- Modular, Easy to Install

- Abrasion Resistance

- Excellent

- Operating Temperature

- -20°C to +70°C

- Impact Resistance

- High

Polyurethane Screen Panel Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 10 Days

About Polyurethane Screen Panel

Our company deals in manufacturing and supplying of heavy duty Polyurethane Screen Panel that can be used in mining applications. It is made up of high density polyurethane that gives high strength to weight ratio with excellent chemical and abrasion resistance. The size and thicknesses of these products can be customized as per the order placed by our customers and applications where it is going to be installed. The offered Polyurethane Screen Panel is highly durable and chemical resistant that result in high durability and chemical resistance. Buy from us this sheet in customizable sizes with minimum order quantity of 1000 pieces.

Exceptional Durability and Performance

Manufactured for industrial-grade screening, these polyurethane panels feature high tensile strength and superior resistance to abrasion and impact. Their extended lifespan ensures cost-effective performance, reducing downtime and maintenance in critical operations such as mining, aggregate processing, and sieving.

Versatile Design for Varied Applications

Available in thicknesses from 15mm to 50mm and in multiple opening typessquare, slotted, and fine mesh. Their smooth or anti-clogging surface adapts to wet or dry screening, giving users flexibility across different operational demands. Custom sizes and finishes are offered to meet specific requirements.

Easy Modular Installation

The polyurethane screen panels are designed for modular assembly, enabling quick installation and replacement. This user-friendly approach helps streamline maintenance, ensuring consistent productivity while supporting both standard and customized panel sizes for diverse screening systems.

FAQs of Polyurethane Screen Panel:

Q: How are Polyurethane Screen Panels installed in vibrating screens or sieving equipment?

A: Polyurethane Screen Panels use a modular design that allows for simple installation. They can be easily fitted, replaced, or customized according to the equipments layout, minimizing downtime and ensuring a secure, stable fit during operation.Q: What types of openings are available in Polyurethane Screen Panels, and which applications are they suitable for?

A: These panels come with square, slotted, and fine mesh openings. Square apertures cater to general-purpose screening, slotted types are suitable for precise grading, and fine mesh is ideal for fine material separation, adaptable for mining, aggregate, and other industrial screening processes.Q: When is it beneficial to use polyurethane panels instead of traditional metal screens?

A: Polyurethane panels are highly advantageous in scenarios demanding superior abrasion and impact resistance, such as wet and dry screening in mining and aggregates. Their extended service life and anti-clogging properties make them preferable over metal screens for continuous, heavy-duty use.Q: Where can customized polyurethane screen panels be obtained for specific screening requirements?

A: Custom sizes and specifications of polyurethane screen panels are available from manufacturers, suppliers, or traders in India upon request. This allows users to tailor the panels for unique industrial screening systems or specific operational needs.Q: What is the process for maintaining Polyurethane Screen Panels to ensure long service life?

A: Routine visual inspections for wear and timely replacement of damaged panels contribute to maximizing lifespan. Their high abrasion resistance and modular installation simplify maintenance, keeping operations efficient and reducing the risk of costly downtime.Q: How does the smooth or anti-clogging surface benefit wet and dry screening operations?

A: A smooth or anti-clogging finish on the screen panels minimizes blockage and material build-up during screening, thereby improving throughput and efficiency in both wet and dry processes. This feature promotes consistent particle separation and less frequent cleaning interventions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pu Mat Panels Category

Colored PU Mat Panel

Minimum Order Quantity : 1 , , Piece

Size : Standard and Custom Sizes Available

Material : Polyurethane (PU)

Grade : Industrial Grade

Classification : Other, Polyurethane Panels

PU Mat Panel

Minimum Order Quantity : 1 , , Piece

Size : Customized (Standard: 1000 mm x 500 mm)

Material : Polyurethane Foam

Grade : Other, Industrial

Classification : Other, Building Insulation Panel

Polyurethane Screen Deck Panel

Price 3500 INR / Piece

Minimum Order Quantity : 1000 Pieces

Size : Customizable or Standard sizes (as per requirement)

Material : Polyurethane

Grade : Other, Industrial

Classification : Other, Screen Deck Panel

Polyurethane Modular Screen Panel

Price 3500 INR / Piece

Minimum Order Quantity : 1000 Pieces

Size : Modular size, customizable as per requirement

Material : Polyurethane

Grade : Other, Premium

Classification : Other, Industrial Screen Panel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS