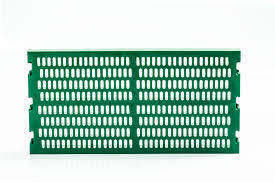

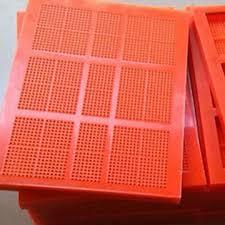

Polyurethane Modular Screen Panel

Price 3500 INR/ Piece

Polyurethane Modular Screen Panel Specification

- Classification

- Industrial Screen Panel

- Type

- Modular Polyurethane Screen Panel

- Grade

- Premium

- Purity

- High (Polyurethane Material)

- Application

- Screening, Sizing, Dewatering in Mining and Quarry Industries

- Color

- Yellow

- Form

- Panel

- Size

- Modular size, customizable as per requirement

- Material

- Polyurethane

- Tensile Strength

- Excellent due to reinforced construction

- Aperture Shape

- Square, Rectangular or Slot as per demand

- Service Life

- Extended wear life due to abrasion resistance

- Temperature Resistance

- -30°C to +80°C

- Surface Finish

- Smooth or textured as required

- Installation Method

- Modular fastening, snap or pin system

- Impact Resistance

- High

- Open Area

- 35% - 50% (depending on design)

- Hardness

- 65 - 90 Shore A

- UV Stability

- Good, suitable for outdoor applications

- Aperture Size

- 0.2 mm to 50 mm

Polyurethane Modular Screen Panel Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 10 Days

About Polyurethane Modular Screen Panel

We are one of the leading manufacturers and suppliers of Polyurethane Modular Screen Panel that is commonly used within industrial applications such as mining, cement manufacturing, and many more for screening of raw materials. It is available in various sizes that can be customized as per the order placed by our customers. The high chemical and abrasion resistance of this panel makes it highly demanding among our customers. Bu from us this top-grade Polyurethane Modular Screen Panel as per your requirements with supply ability of 1000 pieces per day.

Superior Durability For Demanding Applications

Engineered for mining and quarry environments, this screen panels abrasion resistance, high tensile strength, and remarkable impact resistance ensure longevity even in the harshest conditions. The polyurethane material is formulated for excellence and extends service life, reducing replacement cycles and maintenance costs for operators.

Customizable Modular Design

Designed to meet specific operational needs, the modular panels can be tailored in size, aperture shape, and finishoffering square, rectangular, or slot openings in a range of sizes. The snap or pin system makes installation efficient and secure, while the panels adapt effortlessly to various screening, sizing, and dewatering requirements.

Outstanding Performance & Versatility

Suitable for temperatures from -30C to +80C and outdoor applications thanks to its UV stability, the panel maintains performance in challenging environments. Its smooth or textured surface allows users to optimize material flow and prevent blockages, making it suitable for a multitude of industrial screening needs.

FAQs of Polyurethane Modular Screen Panel:

Q: How are the polyurethane modular screen panels installed?

A: These panels utilize a modular fastening system, such as snap or pin attachments, allowing for fast and secure installation or replacement. This method minimizes downtime and supports easy maintenance in busy industrial settings.Q: What advantages does polyurethane material offer over traditional screening panels?

A: Polyurethane delivers high abrasion resistance, increased impact strength, and a longer lifespan. Its UV stability and wide temperature tolerance make it ideal for both indoor and outdoor mining and quarry operations.Q: When should I choose square, rectangular, or slot apertures?

A: The choice depends on your specific screening application. Square apertures offer consistent sizing; rectangular or slot apertures are optimal for dewatering or separating elongated particles. Custom aperture sizes (0.250 mm) are available to suit various materials and operational needs.Q: Where can these modular screen panels be used?

A: Primarily designed for mining and quarry industries, they are ideal for screening, sizing, and dewatering applications in processing plants requiring robust, premium screening solutions.Q: What is the service life of these panels?

A: Thanks to the abrasion-resistant and reinforced construction, these panels offer an extended service life compared to conventional screens, making them a cost-effective solution for high-throughput operations.Q: Describe the process for customizing panel size and aperture.

A: Clients can specify their required panel dimensions, aperture shapes (square, rectangular, slot), and sizes. The manufacturer provides tailored designs to ensure an exact match with existing screening equipment and operational goals.Q: What are the benefits of a smooth versus a textured surface finish?

A: A smooth finish is effective for materials prone to sticking, improving flow and reducing blockages. A textured finish can enhance particle stratification. Both options help optimize screening efficiency based on the application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pu Mat Panels Category

Colored PU Mat Panel

Minimum Order Quantity : 1 , , Piece

CAS No : 9009545

Size : Standard and Custom Sizes Available

Type : Other, Colored PU Mat Panel

EINECS No : 6184989

PU Mat Panel

Minimum Order Quantity : 1 , , Piece

CAS No : 9009545

Size : Customized (Standard: 1000 mm x 500 mm)

Type : Other, PU Mat Panel

EINECS No : 5000450

Polyurethane Screen Deck Panel

Price 3500 INR / Piece

Minimum Order Quantity : 1000 Pieces

CAS No : 9009545

Size : Customizable or Standard sizes (as per requirement)

Type : Other, Polyurethane

EINECS No : 6183840

Polyurethane Screen Panel

Price 3500 INR / Piece

Minimum Order Quantity : 1000 Pieces

CAS No : 9009545

Size : Standard and Customized Sizes Available

Type : Other, Polyurethane Screen Panel

EINECS No : 6184989

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS